Bicell® polypropylene honeycomb panels – Producer IPB

IPB produces and processes Bicell® polypropylene sheets with honeycomb structure for companies in Belgium, Europe, and beyond.

Looking for lightweight, strong, and versatile plastic sheets with a cellular or honeycomb structure? Discover our exclusive product Bicell®. Innovative polypropylene sheets, perfectly suited for protective packaging, floor protection, cargo area lining, and more.

What are polypropylene sheets with cellular or honeycomb structure?

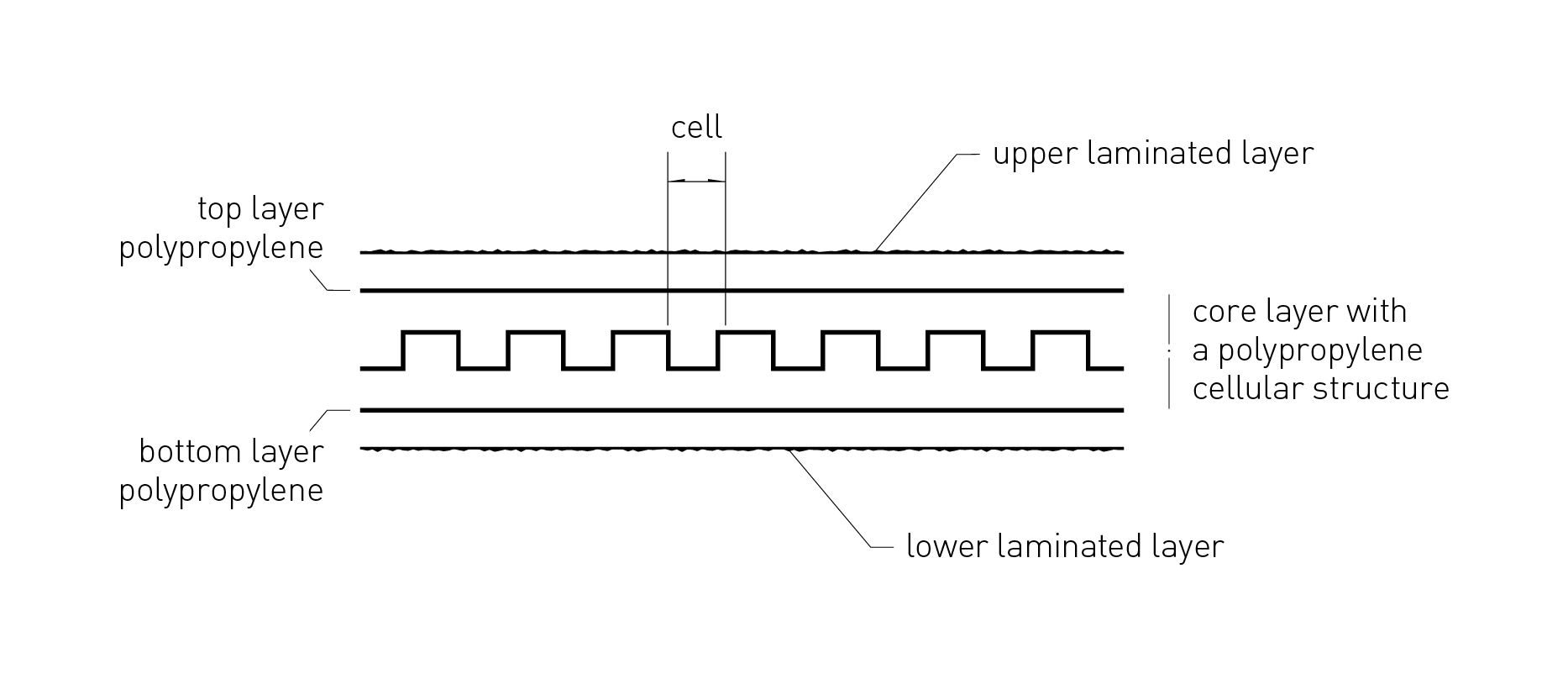

Polypropylene sheets with cellular or honeycomb structure consist of multiple layers with a core of hollow cells. This smart core design provides an ideal balance between weight, stiffness, and durability. They are also moisture-resistant, chemically resistant, and fully recyclable.

Our product Bicell®

- Lightweight and strong

- Water-resistant and chemically resistant

- 100% recyclable

- Wide choice of sizes and thicknesses

- Custom-made on request

For which applications are these sheets suitable?

- Protective packaging

- Floor and wall protection

- Automotive: lining of cargo spaces, …

Why choose IPB?

At IPB we combine years of experience with high-quality plastic solutions. We deliver quickly and flexibly, think along with you based on your application, and provide customized solutions.

Frequently asked questions about honeycomb and cellular structure sheets

What is the difference between Bicell® and Triacell®?

Both are polypropylene sheets with a cellular core. Triacell® is finished with a flat top and bottom surface, making it ideal for printing.

Are these sheets suitable for outdoor use?

Yes, our sheets are moisture- and water-resistant and, with the addition of an anti-UV additive, also suitable for temporary outdoor use.

Are the sheets recyclable?

All sheets are made of 100% recyclable polypropylene.

IPB is the specialist in the production and processing of polypropylene corrugated sheets and polypropylene sheets with cellular structure for companies in Belgium, Europe, and beyond.

Discover our exclusive products:

- Biplex®: polypropylene (PP) corrugated sheets for protection, lost formwork, packaging, signage, printing, …

- Biplex+®: micro-perforated Biplex polypropylene (PP) under-roof sheets.

- Bicell®: polypropylene (PP) honeycomb sheets for protective packaging, floor and wall protection, lining cargo spaces, …

- Triacell®: polypropylene (PP) honeycomb sheets with smooth or rough top and/or bottom for lining cargo spaces, pallet boxes, printing, decorative panels, exhibition stand construction, flight cases, food packaging, …

Request a visit or become a distributor

Are you a private individual? Find a distributor

Applications

-

Coil reels

-

Personalised packaging

-

Automotive parcel shelf

-

Floor protection

-

Protective packaging

-

Cargo space covering

-

Packaging

-

Container sleeves

Other applications:

- Packaging: with Bicell® you can manufacture strong packaging in countless shapes.

- Sleeves: With its high rigidity, Bicell® offers a firm base for sleeves and coverings for wire containers.

- Promotional items / displays: Different colours or a personalised pre-printed film give various promotional items an extra dimension which makes it more attractive. The combination of different colours on top or bottom gives a special appearance to displays, exhibition stands, ...

- Shockproof / protective: A foam layer laminated onto the Bicell® sheet, prevents damage to your products.

- Automotive: Finishes for cargo spaces of delivery vans are perfectly possible with Bicell®.

- Textile: the use of several non-woven textiles or spun bond fabrics gives Bicell® a high-quality finish.

- Nutrition: Bicell® is ideal for food packaging. The lamination of a personalised film gives your product a better visibility.

- Protective packaging: the use of an insulating film or a soft textile layer make sure your goods are transported and delivered in perfect condition.

Characteristics

Treatments

Processing

Laminating

Bicell® can be laminated with several different finishing layers. These finishing layers create an extra dimension for Bicell®. This enlarges the number of applications and gives Bicell® some new characteristics such as:

- Conductive / ESD: this causes the Bicell® sheet to become electrically conductive. This creates the perfect packaging solution for products that are sensitive to electric discharge.

- Shockproof / protective: : A foam layer laminated onto the Bicell® sheet, prevents damage to your products.

- Anti-slip: prevents people or goods to slip away on a Bicell® sheet and therefore prevents injuries and damage.

- Personalised prints: with a pre-printed film you can personalise your application in detail: an attractive packaging. An imitation of wood, textile or other materials are possible.

- Textile: the use of several non-woven textiles or spun bond fabrics give Bicell® a high-quality finish, thus avoiding scratches.

- Insulating: aluminium coloured films give packaged goods the capability of maintaining its temperature, either cold or hot.

- VCI: specifically developed additives prevent the oxidation of metal parts.

- Luxury: laminating a silver or gold foil onto the sheet, gives your packaging a luxury appearance.

- Other laminates are on request: tell us your specific need and we will look for a suitable solution.

Specifications

PHYSICAL PROPERTIES

| Specific gravity PP | ISO 1183 | g/cm3 | 0,907 |

| Water absorption | ISO 62 | % | 0,02 |

MECHANICAL PROPERTIES

| Tensile strength (50 mm/min) | ISO 527 | MPa | 38 |

| Elongation at break (50 mm/min) | ISO 527 | % | 800 |

| Flexural modulus | ISO 178 | MPa | 1250 |

| Impact strength Izod (23°C) | ISO 180 | kJ/m² | 80 |

| Shore D hardness | ISO 868 | - | 66 |

| Compression strength 3,0mm/600g | Internal IPB | N/cm² | >35 |

| Compression strength 3,5mm/800g | Internal IPB | N/cm² | >95 |

| Compression strength 3,5mm/1000g | Internal IPB | N/cm² | >148 |

| Compression strength 4,0mm/1250g | Internal IPB | N/cm² | >200 |

| Compression strength 4,0mm/1500g | Internal IPB | N/cm² | >200 |

THERMAL PROPERTIES

| Coefficient of linear expansion | ASTMD696 | mm/m°C | 0,18 |

| Specific Heat | DSC | J/g°C | 1,68 |

| Heat deflection temp.(0,46 MPa) | ISO 75 | °C | 78 |

| Heat deflection temp.(1,82 MPa) | ISO 75 | °C | 52 |

| Vicat softening point (1 kg) (10N) | ISO 306 | °C | 148 |

| Vicat softening point (5 kg) (50N) | ISO 306 | °C | 78 |

OPTICAL PROPERTIES

| Light transmission (1500g/m²) | Internal IPB | % | 40 |

ELECTRICAL PROPERTIES

| Surface resistivity | ASTMD257 | Ω | ca. 1013 |

| Dielectric constant (at 1 MHz) | ASTMD150 | - | 2,25 |

| Dissipation factor (tgδ at 1MHz) | ASTMD150 | - | < 5 x 10-4 |

| Dielectric strength (500V/sec) | ASTMD149 | kV/mm | 70 |

Delivery program

Different colours for top and bottom layer are possible. Possibility to laminate on both sides.

Standard thickness/weight combinations

| Thickness vs weight/m² | 600 gr | 800 gr | 1.000 gr | 1.250 gr | 1.500 gr |

| 3.0 mm | ° | ||||

| 3.5 mm | ° | ° | |||

| 4.0 mm | ° | ° |