Triacell® is an extruded polypropylene sheet consisting of 3 layers. The central layer is a cell structured layer. The top and bottom layer are 2 smooth layers.

The cell structure is the core of this sheet. This gives Triacell® its principal characteristics: high rigidity and high compression strength, combined with a light weight.

- smooth top and bottom layer

- high compression strength

- light-weight

Applications

-

Protective packaging

-

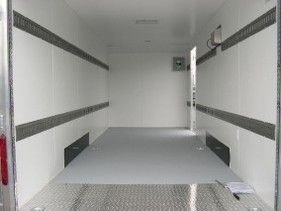

Covering of cargo spaces

-

Container sleeves

-

Floor and wall panels (exhibition stands)

-

Flightcases

Other applications:

Construction applications, displays, pallet protection, boxes, dividers, …

Characteristics

Treatments

Processing

Specifications

PHYSICAL PROPERTIES

| Specific gravity PP | ISO 1183 | g/cm3 | 0,907 |

| Water absorption | ISO 62 | % | 0,02 |

MECHANICAL PROPERTIES

| Tensile strength (50 mm/min) | ISO 527-2 | MPa | 27-33 |

| Flexural modulus | ISO 178 | MPa | 1350 |

| Impact strength Izod (23°C) | ISO 180 | kJ/m² | 5 - 25 |

| Impact strength Izod (-20°C) | ISO 180 | kJ/m² | 0 - 6 |

| Compression strength at maximum 2,4mm/450g | external lab | N/cm² | 60 |

| Compression strength at maximum 2,7mm/600g | external lab | N/cm² | 130 |

| Compression strength at maximum 3,4mm/900g | external lab | N/cm² | 136 |

| Compression strength at maximum 5,7mm/1600g | external lab | N/cm² | 176 |

| Compression resistance (at 1000N) 2,4mm/450g | external lab | N/cm² | < 30% |

| Compression resistance (at 1000N) 2,7mm/600g | external lab | N/cm² | < 30% |

| Compression resistance (at 1000N) 3,4mm/900g | external lab | N/cm² | < 20% |

| Compression resistance (at 1000N) 5,7mm/1600g | external lab | N/cm² | < 15% |

| Impact resistance 2,4mm/450g | Falling dart drop | no effect < 0,30m | |

| Impact resistance 2,7mm/600g | Falling dart drop | no effect < 0,40m | |

| Impact resistance 3,4mm/900g | Falling dart drop | no effect < 0,80m | |

| Impact resistance 5,7mm/1600g | Falling dart drop | no effect < 1,00m | |

| Flexural Break resistance 2,4mm/450g | ISO 178 | N/mm² | 3,75 |

| Flexural Break resistance 2,7mm/600g | ISO 178 | N/mm² | 3,2 |

| Flexural Break resistance 3,4mm/900g | ISO 178 | N/mm² | 8,28 |

| Flexural Break resistance 5,7mm/1600g | ISO 178 | N/mm² | 27,4 |

THERMAL PROPERTIES

| Coefficient of linear expansion | ASTMD696 | mm/m°C | 0,18 |

| Specific Heat | DSC | J/g°C | 1,68 |

| Heat deflection temp.(0,46 MPa) | ISO 75 | °C | 78 |

| Heat deflection temp.(1,82 MPa) | ISO 75 | °C | 52 |

| Vicat softening point (1 kg) (10N) | ISO 306 | °C | 148 |

| Vicat softening point (5 kg) (50N) | ISO 306 | °C | 78 |

ELECTRICAL PROPERTIES

| Surface resistivity | ASTMD257 | Ω | ca. 1013 |

| Dielectric constant (at 1 MHz) | ASTMD150 | - | 2,25 |

| Dissipation factor (tgδ at 1MHz) | ASTMD150 | - | < 5 x 10-4 |

| Dielectric strength (500V/sec) | ASTMD149 | kV/mm | 70 |