Veralite 200®: Extruded plastic sheet based upon polyester PETG.

Veralite 200® is an extruded transparent plastic sheet based upon PETG (Glycol modified Polyethylene Terephthalate). PETG has the advantage of not crystallizing when heating. This makes it easily processable.

Veralite 200® is the best choice for complex processing and detailed thermoforming.

- excellent impact resistance

- hot bending

- best material for thermoforming

- easily processable

Applications

-

Vending machines

-

Baby incubators

-

Thermoformed parts

-

Food dispensers

-

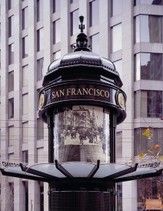

Kiosks

-

Chocolate moulds

-

Signs

-

Thermoformed signs

-

POS/POP-items

-

Magazine displays/shelves

Other applications:

Product displays, safety guards, storage trays,…

Characteristics

Processing

Specifications

PHYSICAL PROPERTIES

| Specific gravity | ISO 1183 | g/cm3 | 1,27 |

| Water absorption | ISO 62 | % | 0,15 |

MECHANICAL PROPERTIES

| Tensile strength | ISO 527 | MPa | 51,5 |

| Elongation at break | ISO 527 | % | > 100 |

| Tensile modulus | ISO 527 | MPa | +- 2200 |

| Impact strength unnotched | ISO 180 | kJ/m² | no burst |

| Impact strength notched | ISO 180 | kJ/m² | 9,0 |

| Rockwell hardness | DIN 2039 | M / R | M85 / R115 |

THERMAL PROPERTIES

| Coefficient of linear expansion | ASTMD696 | mm/m°C | + 0,060 |

| Specific Heat | DSC | J/g°C | 1,13 |

| Heat deflection temp.(0,45 MPa) | ISO 75 | °C | 72 |

| Heat deflection temp.(1,82 MPa) | ISO 75 | °C | 68 |

| Vicat softening point (1 kg) | ISO 306 | °C | 82 |

| Vicat softening point (5 kg) | ISO 306 | °C | 78 |

OPTICAL PROPERTIES

| Light transmission | ASTMD1003 | % | 86 - 90* |

| Haze | ASTMD1003 | % | < 1 |

| Gloss (60° angle) | ASTMD1003 | units | 159 |

ELECTRICAL PROPERTIES

| Surface resistivity | ASTMD257 | Ω | 1*E15 |

| Dielectric constant (at 1 MHz) | ASTMD150 | - | 2,4 |

| Dissipation factor (tgd, 1 MHz) | ASTMD150 | - | 0,020 |

| Dielectric strength (500V/sec) | ASTMD149 | kV/mm | 16 |

| Glow wire test | IEC 695/2.1 | C° | 650 |

BARRIER PROPERTIES

| Permeability for water vapour | ASTMF372 | g/mm/m²/24h | 1,5 |

| Gas permeability for CO2 | ASTMD1434 | g/mm/m²/24h | 49 |

| Gas permeability for O2 | ASTMD3985 | g/mm/m²/24h | 10 |